2024 Regular Maintenance

AMI – ASPHALT MANAGEMENT INC., Flushing, MI

Two-page PDF Document:

Est_15667_from_Asphalt_Management_Inc._5276

One-page PDF Document:

Woods West

2023 Regular Maintenance

AMI – ASPHALT MANAGEMENT INC., Flushing, MI

One-page PDF Document:

2023-Est_14481_from_Asphalt_Management_Inc._3128

One-page PDF Document:

Est_14453_from_Asphalt_Management_Inc._13584

2021 Regular Maintenance

AMI – ASPHALT MANAGEMENT INC., Flushing, MI

One-page PDF Document:

Est_12430_from_Asphalt_Management_Inc._18004

ASI PAVING, Pontiac, MI

(ASI Document, see bottom of page)

ASI MEETING NOTES:

• Road has been well-maintained

• No structural, safety nor surface/base deficiencies suggest need for immediate road replacement

• ASI Performed core sample work to determine the depth of our asphalt, which is 5-inches

• Although not a formal or informal warranty, it was suggested that a 2-inch mill and resurface would last about 10 years. and a 5-inch mill and replacement would last about 20 years – assuming regular maintenance. Weather and maintenance practices ultimately impact road life.

• A 2-inch mill and resurface would show the reappearance of cracks in 1-2 years. A 5-inch mill and replacement would give us 3-5 years before cracks would appear. Always with the caveat of weather, use of ice melt, etc.

• Based on visual inspection, there were no areas that would require undercutting and replacement of base/sub-base or subgrade. Should they find sub-surface areas that need replacement, they quote a price of $48/ton.

• After milling has been completed, ASI inspects the sub-surface and determines if any needs to be replaced, so there is no need for pre-contract engineering work.

• No contractors have included the following as part of their bid price: bonds, permits, testing, engineering, layout, inspections, excavation, butt joints, undercutting, traffic control/flagmen, barricades in ROW, signage, bollards, irrigation/utility repairs (including private utility lines including street lights), winterization (including blankets and additives to concrete) or landscape restoration.

• When we pursue a contract, we should request estimates for the items listed immediately above.

• For all bids, we should plan for an additional 10% – 20% of the total project cost available to cover any unexpected services including sub-surface replacement.

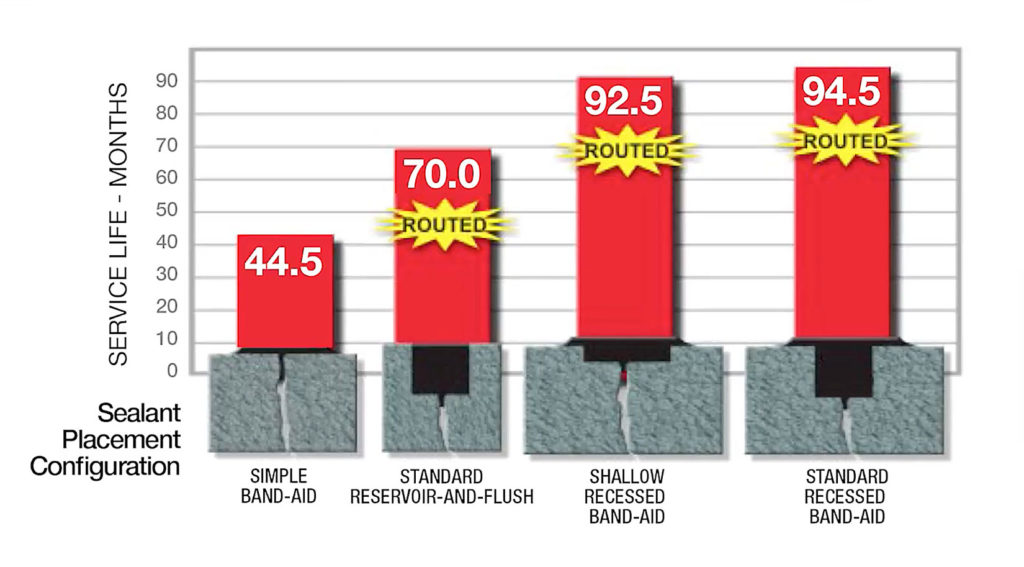

• Unique to ASI’s advice was in the area of long-term maintenance. The maintenance contractors they work with use exclusively Pavement Crack Routing, instead of just filling the crack. Routing costs more, but lasts longer and leaves behind a more attractive crack repair due to a more uniform edge. Routing can be combined with sealing, like we have been doing, or applying a “band-aid” layer over the routed crack fill.

The information below is not from one of ASI’s suggested contractors, it’s information I found online. The video is intended for contractors:

• non-routed sealed crack (like we’ve been doing) lasts 1-4 years

• a routed sealed crack (standard lasts 7 years or longer

• 80% of crack repair cost is labor

(there are variations of how to execute the routing and finishing that impact life)

In My Opinion: The routing process is something that should be explored after a new road is in place. It will improve the overall appearance of the road and isn’t likely to add to the overall cost to maintain. But actual quotes are needed to know that for certain.

ASI PAVING, Pontiac, MI

Two-page PDF Document:

Wood west Condo Association

One-page PDF Document:

Woods West Condos TO